Germany—the European manufacturing powerhouse—has set a new course for its future high-tech industry. Under the strategy Industry 4.0, Germany is in transition to the fourth industrial revolution. Cloud computing, internet of things, real-time sense-and-response technologies, cloud-based services, big data analytics, robotics, artificial intelligence, 3D printing and so on are foreseen to revolutionise how we make things and deliver services today. Indeed, our factories and businesses are changing. But where does this leave lean? Will developments in technology leave lean irrelevant? Is lean a hype that is soon to end?

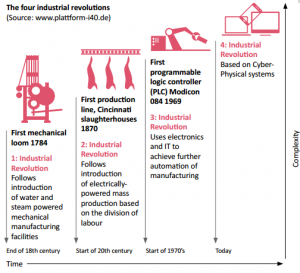

The four industrial revolutions

Industry 4.0 is the current high-tech manufacturing strategy of the German government. If Germany thinks it is the right direction for its future competitiveness, we should all probably listen. Industry 4.0 was first presented as a concept in 2011, and has been researched, debated and further defined since then. Industry 4.0 is based on tight integration of modern information technology in the manufacturing and supply chain operations (called cyber-physical production systems). The objective is to create the intelligent factory during the two next decades.

Industry 4.0 refers to the fourth industrial revolution. The first industrial revolution started in Great Britain and took place around 1760-1840. It involved the establishment of factories using mechanical machines and steam or water power to move from craft production to industrial manufacturing in the textile industry. A century later, around 1870-1930, the second industrial revolution took advantage of electrical power and moving assembly lines to introduce the era of mass production. The third industrial revolution started around 1970, and use information technology and operations research to transform how we plan, control and automate the production. We got numerically controlled machines (CNC), material resource planning software (MRP, later ERP), computer aided engineering, -design and -manufacturing software (CAE/CAD/CAM), and automated material handling conveyors and robots. It is within this paradigm of industrial production lean was born—partly in parallel-, partly in competition- and partly in cooperation with the digitalisation of the workplace. Today, state-of-the-art manufacturing combines the philosophy of lean production with automation and IT technology.

We’re now in the beginning of the fourth industrial revolution. This introduces the internet of things in manufacturing; the digital and physical worlds merge. One central idea is to move from a centralised to a desentralised production model where materials and machines communicate with each other in real-time without the need of a fixed production plan. The shop-floor of smart factories will be embedded within the global networks of supply and demand through the cloud. It will be self-diagnosing, self-optimising and self-configuring. The result is intelligent value-creating supply chain networks that autonomously and automatically respond to changes in end-demand. Clearly, Industry 4.0—when realised— will revolutionise the current business models of how we design, manufacture and deliver products and services. Is the era of lean manufacturing soon to end?

Lean in industry 4.0

Lean will not fade with Industry 4.0. Quite the opposite, lean principles are likely to become more important. The fourth industrial revolution can enable the true lean enterprise. Industry 4.0 permits a much richer understanding of the customer demand and allows the immediate sharing of the demand data throughout complex supply chains and networks. Smart factories can produce faster with less waste. Industry 4.0 enables a much quicker one-piece flow of customised products. It has the potential to radically reduce inventories throughout the supply chain.

On the other side, with radical changes in the environment come changes in lean as a practice. Assumedly, there will be less physical kanban cards, less andon cords, less whiteboards and similar technical lean solutions in future factories. But that is not a pity; Toyota has never looked at these tools and practices as objectives in their selves, they are just technical solutions to minimise wasteful processes. One of the most promising advances in technology is the possibility to share—and act on—real-time information in a coordinated end-to-end supply chain. This enables a radically improved form of instant just-in-time pull production.

In short, Industry 4.0 technologies may be exactly what we need in order to create lean supply chains and networks. Lean is about doing more with less—today and in the future.

Further reading: