Ian Machan discusses what the best ideas for developing lean are. Would we best served in investing in the future or seeking to better what we already have?

If you could invest in either providing a thousand specially designed kits of Lego blocks to introduce lean thinking to 16 year-olds or supply funding to support detailed research in lean development, which would you choose?

Being forced into such a binary decision will lead to consideration about which of these two approaches will deliver the greatest value. The former would provide thousands of new adults with practical experience in problem solving, understanding wastes and seeing value appear and disappear. The latter would move our understanding of lean forward and maybe lead to improved techniques for later dissemination.

Should we broaden the practice of lean or deepen its intellectual provenance?

The word practice, above, is key. Practice implies there is a skill to be learnt, improved and exercised. There are hundreds of examples in modern work-places where the skill of applying lean tools and approaches is lacking and hence improvement does not happen. In comparison, there are relatively few examples that are only solved through high-level lean expertise. Empowering people to work in teams, monitor and solve their own problems is often used by some large businesses as a key performance indicator to track their lean implementations.

Let’s take a look at some published works in the lean and operations field:

John Bicheno, of the University of Buckingham, has a list of his top 100 lean related books. I am sure you can glance down the list and see many old favourites. But let’s take two examples:

- Factory Physics by Wallace Hopp and Mark Spearman (which was featured in the September LMJ)

- Learning to See by Mike Rother and John Shook.

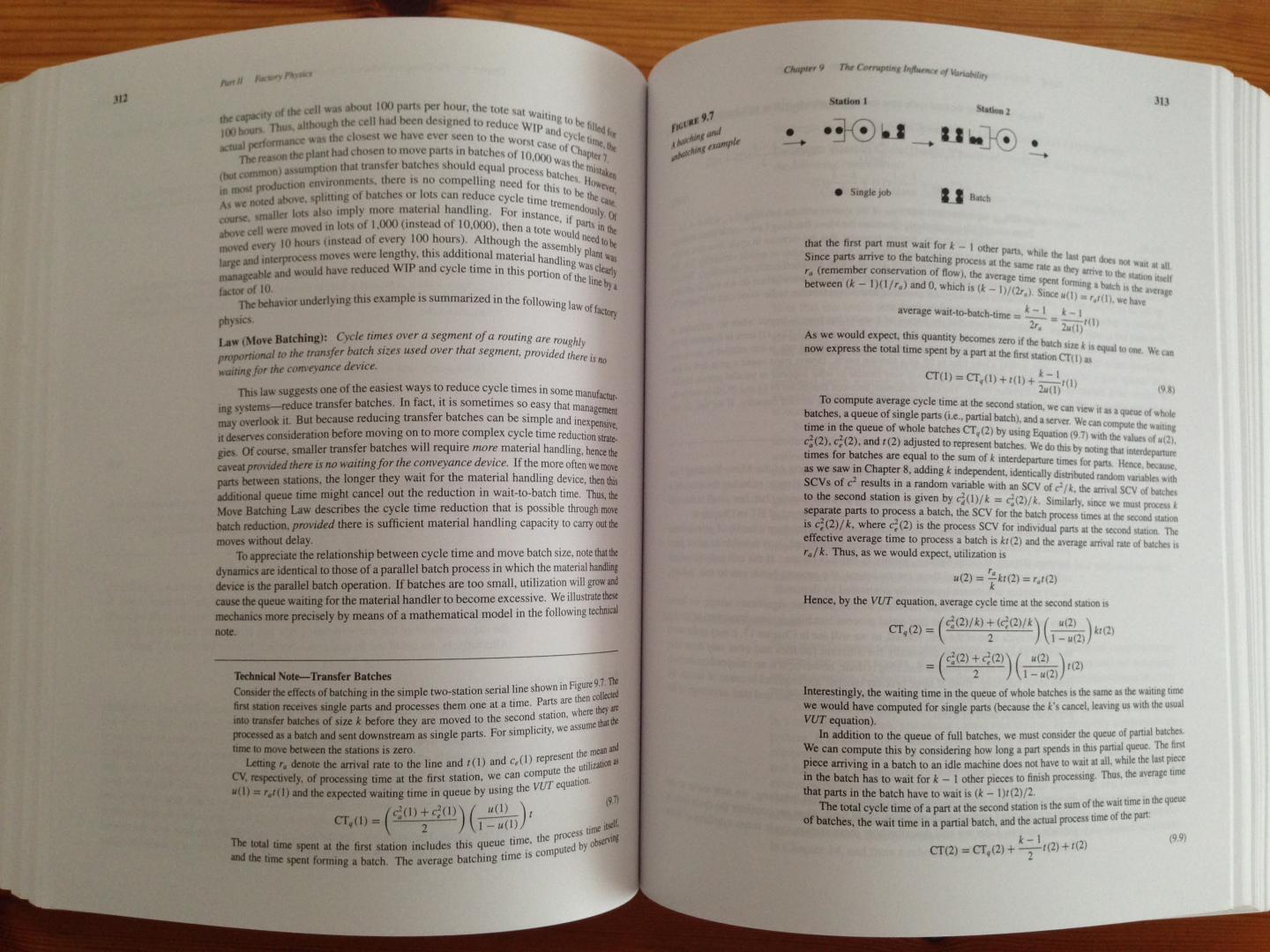

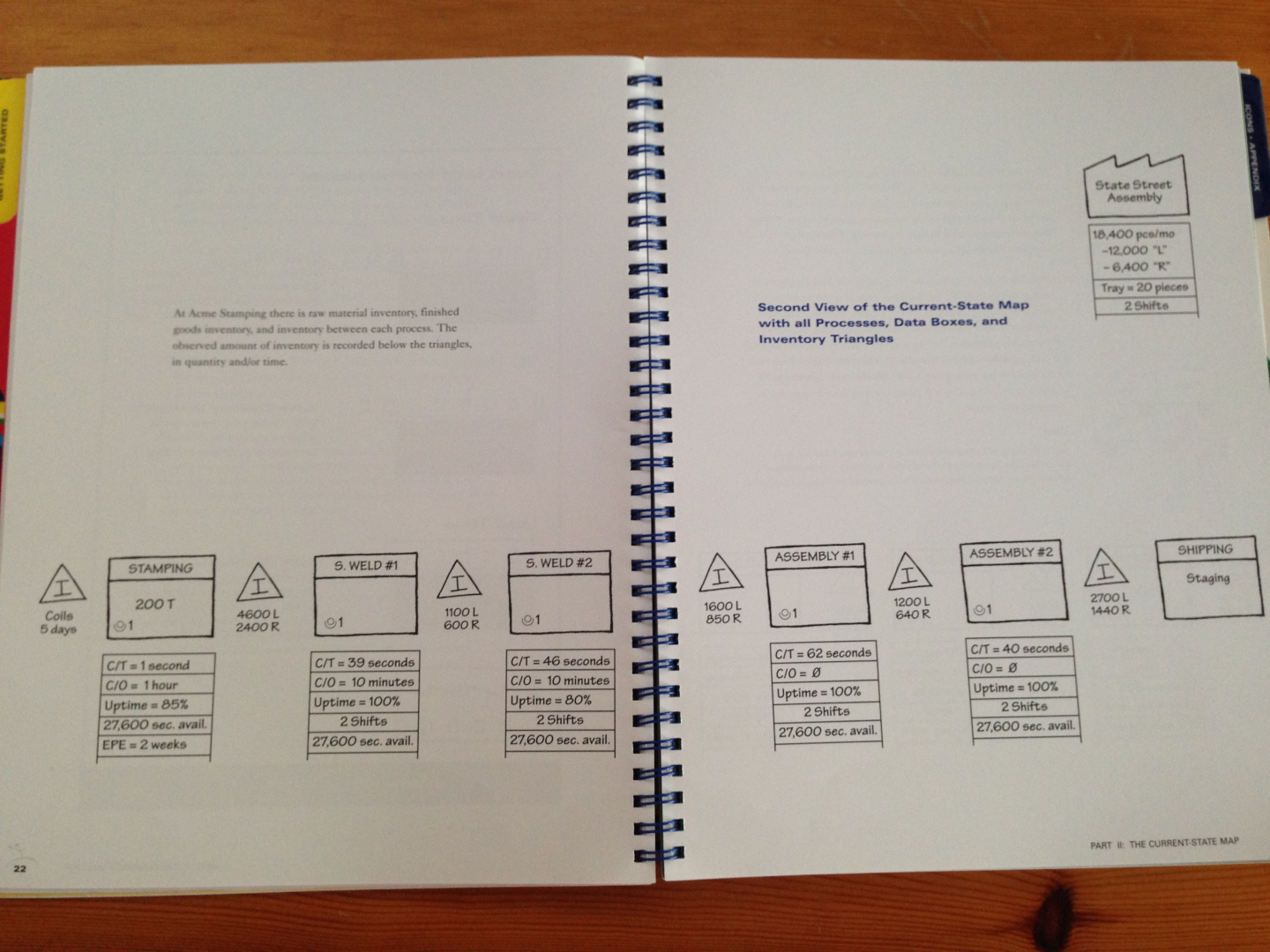

Looking inside both at random, this is what we see:

The equations in the first will discourage 90% of almost any group of people, while you could argue the graphic value stream depiction could be successfully explained to more than 90%. We all love an equation, but simple concepts often work best. Focusing on observation, clear thinking around value and waste reduction. Not large investment into research grants into the top end of lean.

Let’s take an even more extreme view. We are all used to black/green belt symbols, but imagine if a standardised degree was constructed and taught everywhere. A lean institution of some description reviews and authorises the course, and then makes it a requirement for anyone wanting to be a professional lean practitioner; a chartered lean engineer, perhaps. We could protect the status so only registered practitioners can run lean projects.

Alternatively, if the teaching of lean thinking and the practice of lean tools was thought of as basic as learning how to construct spreadsheets, write essays, interpret drawings, measure and cut materials then maybe we could have lean literacy with all of the ensuing benefits. Lean is a skill and requires knowledge but the knowledge is useless without application.

Lego games or PhDs. What’s your view?