By Jeremy Butler

Back in the late 1990s I came back to my family’s engineering business in the Midlands, having spent time working in the US and London. With a degree in economics and two jobs under my belt, I was bright-eyed and bushy-tailed. I had visions of shaking up the fuddy duddy old engineering world. The family business was an aluminium foundry, supplying blue-chip names such as Scania, Volvo Truck, Volvo Penta and Blackstone, later to become part of Valeo, in Sweden, Cummins Engines and Perkins Engines, and IMI Radiators, later to become part of the global Denso group. Other specialist accounts included turbocharger manufacturers, and Hunting Engineering, a defence business. Our production processes covered sand casting, gravity die casting, numerical control (NC) and computer numerical control (CNC) machining, and various leak decay/pressure testing kits.

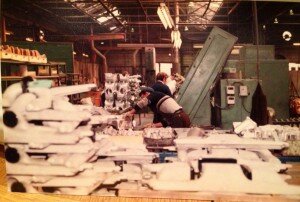

The business had been founded by my grandfather in 1952, and built up by my father into one of the largest independent aluminium foundries in the UK. We had a niche in the supply of air movement parts,usually sand cored and machined by our customers. Our premises were a modern 80,000 square foot unit on an industrial park, with clear departments for core making, casting, fettling/linishing, and final operations such as pressure testing and NC machining.

The business had been historically very successful, however, recent financial performance was weak. As I started to familiarise myself with the day-to-day running of the business, a few things stood out. We were air freighting weekly to Sweden. In fact, we had a standing account with design and manufacturing service provider, ASG, and a weekly meeting between the operations director and the sales director to decide which parts we would deign to send to the customer. This had become learned behaviour, it was just the way it was. Morale was low – there weren’t enough lockers for the men, meaning some had to leave their clean clothes and a towel on top of a locker bank all day, where they gathered dust from the processing operations, not to mention, erratic thermostats in the showers. The lights in the car park were broken, resulting in regular break-ins to cars on dark winter evenings. Our lead time for a batch of parts was a standard 8 weeks, regardless

of what was being ordered.

Our quality statistics were actually very good, however, we achieved this by inspecting the defects, not designing in ‘right first time’ quality. The dies we bought were not designed for ease of processing – for example, a casting has a split line where the die sides meet, and the customer quite rightly did not want any sharp edges there. We would spend an inordinate amount of time sanding the line flat, whereas our competitors had designed a bead line, designed to sit neatly, with rounded edges, thus minimising processing times. Sand cores were stacked on racks, where they rubbed against cardboard spacers. The ‘rubbedaway’ area often became additional cast metal on the inside of the part, which an eagle-eyed assembly worker had spotted,objected to and which we now spent copious time removing – while a few yards away we merrily made and stacked more cores, creating the problem. All of this was set against a backdrop of hisses, as air slowly leaked from joints dotted around the plant. These processes were normal. We were no different to many small and medium enterprises (SME) metal-bashers – aggressive purchasing policies meant that we didn’t have a lot of money to spend. To top it off, our delivery performance was erratic and we were letting customers down, so what were we to do?

The epiphany came in several ways. I was showing a supply quality engineer from Perkins Engines around. I waved a hand at the piles of work in progress (WIP), and said that my biggest issue was throughput of parts, and working capital, and how they were linked. I told him that we needed to liberate the WIP into money, to help us and to give our customers what they were paying for. He told me that I should read James P. Womack and Daniel T. Jones’ Lean Thinking. So I did, and I was captivated. I immediately bought a dozen copies and circulated them.

Job one was to spread the word and to learn. We started by tapping into our customers – all the UK ones were actively pursuing lean in some form, and I was freeseated by Perkins on a kaizen event at their Peterborough plant, facilitated by TBM Consulting. The event blew my mind, not so much for the incremental gains achieved, but for the way it tapped into the people’s knowledge of the work being done. Here was the answer! I read as much as I could very quickly, and quizzed the sensei and lean champions either at, or being retained by, our customers. Our fundamental problem was lack of throughput speed. I wanted our place to flow. I delivered training sessions on lean, waste and value, flow, internal customer/supplier concept and we started planning kaizen blitz events. We had no time to lose. I would joke with the workers on the shop floor, pointing at things – “Is that value-adding? Or waste?” I decided that we had to do two things quickly, firstly, have a blitz event on the shop floor that would physically make a difference to how we were organised, and then take care of the basics for the people. Our first kaizen event was generously facilitated by Perkins, and was, in fact, not aimed at improving the flow of their own products but those of an unrelated company, Denso. The reason for this was the visual impact we were fairly sure this event would have, the parts were large and unwieldy charge air coolers, so any improvement would really grab attention. Using doctored training materials (we had no money, remember), I led the first event. We smashed the modest metrics we’d set ourselves. At the same time, we fixed the car park lights, bought more lockers, fixed the showers and started monthly communication sessions talking about our results (which were terrible) and what we were doing about it (a lot). I also in troduced the concept of a profit share, pledging that 10% of our pre-tax profit would be divided equally amongst all people who had an unblemished attendance record for that month.

The joke was, it was a loss we were sharing initially, but we saw it gradually diminish until we hit the black. I was warned by my fellow directors not to do this, for fears that “the competition will find out ”. But I had nothing to lose. We were slowly going bust. The most moving moment was when we first made a profit – even though we paid the wages by BACS, to maximise the impact we deliberately printed cheques and I handed them out. The profit share was £12.66. Two people hung back, and then came to me, handing the cheques back saying: “we know the business needs this”. To this day, recalling that moment is emotional and underlines for me the massive importance of people in any change initiative.

By now we were looking hungrily at the lean toolbox. Everyone knew the maxim was to get parts made and sold quickly. KPMG approached us as they had funds from their Accelerate programme for struggling SMEs. Using these we started kanban, and I was found by a management consultant from KPMG on the shop floor painting a kanban board. He was gobsmacked and told me: “you’re the MD, you shouldn’t be doing that”. But I believed that I had to model the urgency and belief that we needed in order to survive.

We used the first kanban to pull parts to the “knock out”, an old brick building where air hammers wielded by two Luke Skywalker look-a-likes were used to batter the cores out. Value adding? I don’t think so. A bottleneck? Definitely. I’ll come back to this.

One day I walked by Eddie. Eddie was an older biker, clad in a Harley T-shirt and sporting a ponytail, he was a strong guy. His job was to check the charge air coolers

for flatness. He’d waggle them on a steel plate, then slide a bit of shim under one end, take a massive hammer and bash the other end. Repeat until flat. This was a tiring job, and he was understandably a little vexed, as the colour of the air around him showed. I asked him what he thought we could do. He suggested a couple of air cylinders should take the strain, pressing down on the shim, with the operator simply positioning the shim intelligently to achieve the flatness outcome. I walked him around to our “Heath Robinson” tool room and gave him the time and support to build one. The next day it was working, throughput rocketed and I made Eddie our first roving troubleshooter. It transpired that Eddie could strip and rebuild a motorbike engine, but we had him hammering parts. What a waste.

This was solid testament as to how lean thinking liberated people from dull repetitive work.

Our lean journey had started. We had tapped into the mine of information that was our people. With processing operations largely leaned, it was time to look at casting itself. Die casters were the elite of the shop floor. This was a skilled job, but we’d never taken time to develop standard work, so the nuances of how quickly to pour the metal, or how the die needed tickling to perform best, were not captured. I had regularly heard comments like “only Bob can make that”, to which I’d reply “what if Bob had never been born? Or fell under a bus tonight”? So we started cross training, and visually managing who could do what, and to what level.

Now to wages. We had a mix of piece work and hourly paid, and although the piece work drove quantity, it was coming at the expense of quality. We created an inverted pyramid of hourly pay rates, with each layer equating to the ability to perform certain tasks, this we called the “cell environment”. You were moved up a band only when your colleagues decided, as the team carried the responsibility for the production. At the same time, we created an NVQ in foundry skills, reflecting the structured progression that we had developed. By now the shop floor was looking seriously different. I had moved the aluminium ingot supply onto kanbans, so we were only paying for the metal we pulled from the store, which was now held at the supplier’s risk.

In the monthly communication sessions we always stressed the need to be competitive. Our suppliers and our customers were large organisations. Aluminium is a commodity, and the alloys we bought had their prices published weekly in trade magazine Metal Bulletin. Our price list separated “metal” from “value add”, and metal pricing moved on an escalator, up or down depending on what Metal Bulletin said. The only space we had to make a difference was in our process capability, in other words, how good we were at converting an aluminium ingot into a discrete, engineered component ready to form part of an engine. Being constrained like this was in fact liberating, as it forced us to focus on how we did what we did.

Over the course of two years, the shop floor was reconfigured into cells, with teams working reverse continental shifts. The team leaders managed their own people, and we gave them training around managing conflict, managing ambiguity and financial basics. We had stocks of finished parts, which we physically hid from the shop floor in order to prevent any feelings of complacency that might cause deviation from standard work. The cells were produced to kanbans, and this was all coordinated by Mark, who had risen from packing castings and printing despatch notes, to being the customer liaison and fully responsible for our delivery performance as a business. He was now earning double what he did before, got married and bought a house.

This was the essence of our lean journey. The people made it happen. The knowledge of how to better organise ourselves was within us, we didn’t need telling. We just needed to listen, and then provide the leadership and support to help make it happen. In the old days, people would leave for more money elsewhere, then come back when they realised we weren’t so bad after all. I introduced a rule that if you left, you couldn’t come back. We needed people who wanted to be there, and we had to create an environment whereby people wouldn’t want to leave. I actually broke that rule for one person, but I made such a big deal over it he was genuinely contrite, and became one of the most diligent people in the business. This also applied to some of our best lean practitioners. They were smart people, who had turned their back on school yet had the command of their peers. Left to their own devices they were borderline disruptive, but channelled as improvement champions they soared, as colleagues and as leaders.

Our lean journey achieved so much, we took cost out, improved logistics and made our customers happier. But the really powerful part was how people’s lives were impacted. People like Mark and Eddie, who had fantastic capabilities that we simply weren’t aware of, and we had not taken time to learn about. Their lives changed through our application of

lean principles.

I went on to work for a big consultancy, and went freelance. When I think back, the personal stories of these people resonate with me. Nowadays, in every improvement assignment, I always start with the people. People are the key to any proposed change initiative, and to not realise that, is to squander your most valuable asset. For me, author and poet, Maya Angelou sums up our lean journey: “I’ve learned that people will forget what you said, people will forget what you did, but people will never forget how you made them feel.”